Select a province & language

Entrance to this website assumes you have read and agree to these Legal Terms and Conditions and the Privacy Policy.

Entrance to this website assumes you have read and agree to these Legal Terms and Conditions and the Privacy Policy.

3D printing is having a moment. Given the technology’s relative accessibility (and definite novelty) most of us know someone who’s tried to a print a neon soap dish or a miniature chess set in their basement.

While you can’t custom-print your own convertible just yet, Toyota certainly shortened the ETA with their groundbreaking 3D-printed car seat. Created through a collaboration with the additive manufacturing lab Materialise, the resulting prototype was lighter in weight, and far less cumbersomely designed than conventional seats on the market. Why does weight matter, you ask? “Specifically for automotive parts, weight reduction brings benefits in many different areas. The most evident advantage is that a lighter car uses less energy, which is both a benefit in terms of ecological sustainability as well as improving the vehicle’s performance,” explains Kristof Sehmke, PR Manager at Materialise. “In addition, lighter weight parts could enhance safety since a light car has a shorter brake distance than a heavy car.”

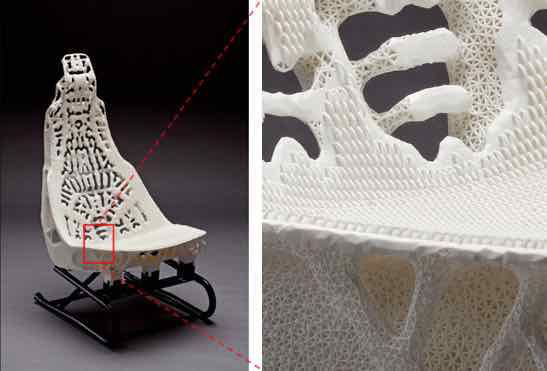

To manage these feats, Materialise used an innovative laser-based slicing and dicing process that reduced the weight of Toyota’s original seat by 18kg (an incredible 72% drop). Beyond its improved efficiency, the final product was also beautiful to behold—equally resembling the human brain’s neurological wiring and an H. R. Giger design straight out of the Alien franchise.

For those who don’t consider themselves “techies” or “makers,” 3D printing uses a specialized machine that lays down successive layers of material to create a three-dimensional object from a digital blueprint. The 2015 Toyota/Materialise prototype marked a landmark in automotive seat design, but perhaps its greatest impact was on the technology that was used to make it: Materialise developed an entirely new cell structure to fill in the lower density areas of the seat, and to cut down on the file size of the finished design, the company pioneered a new method of transmitting 3D printing data.

With technological developments accelerating so rapidly, it’s hard to underestimate the potential of 3D printing on automotive manufacturing. Instead of building everything in multiple factories and shipping these parts around the world, a local factory with 3D printing facilities could produce full-scale vehicles. In addition to saving on the cost of shipping the parts, there’s also a consumer benefit: In the future, we may be able to head to the dealership, select everything from our car’s dashboard display fixtures to our door trim using 3D printing, then drive home with a fully customized product within days.

“When it comes to the automotive industry, we expect that additive manufacturing will play an even more important role in the future as both emerging and established automotive companies are increasingly extracting the benefits of the technology,” notes Sehmke. “However, we believe in using the technology to add value, as opposed to literally reinventing the wheel for the sake of it.”

As noted in the Economist, major manufacturing advances like 3D printing often take time to catch on, and only later does their real significance become apparent. “Throughout the 1980s factory bosses scratched their heads over Taiichi Ohno’s Toyota Production System and its curious methods, such as the just-in-time delivery of parts,” wrote the magazine. “Now it is the global benchmark for factory efficiency.”