Select a province & language

Entrance to this website assumes you have read and agree to these Legal Terms and Conditions and the Privacy Policy.

Entrance to this website assumes you have read and agree to these Legal Terms and Conditions and the Privacy Policy.

Prior to its first resurrection in 2013 our 1990 Toyota Pickup (“Little Red”) had been used hard and left for dead in the back-forty. It had flat tires and a broken windshield that leaked like a sieve. Long grass consumed the 25-year-old minitruck. Despite the Pickup’s unfortunate condition, we knew in our hearts that this truck would make a stellar overland vehicle for tackling the Pan-American Highway. We sold our new Chevrolet Silverado and never looked back.

We spent four weekends building the Pickup for the trip. Not four weeks, four weekends. This limited period of time didn’t allow for anything close to perfection, but it was more than enough to build a capable overland truck to get us to Ushuaia, Argentina and back. This minitruck embarked on a 65,000-kilometre Pan American adventure it couldn’t have dreamed of during its time wasting away in the backyard. Using many Toyota Genuine parts our little Pickup brought us across the Bolivian salt flats, through the Patagonian mountains, to the southern tip of Argentina and back home again.

Four years after our return we’re refreshing the truck for more overland adventures. We find that it takes less effort in the long run to complete a major service to the truck before embarking on month or year-long overland trip. By replacing what we can ahead of time in a controlled environment (read: clean shop) it saves us time and money on the road. Sure, we could have hopped in our relatively new 2008 Toyota Tundra and traveled with power and air-conditioned comfort, but there’s something special about keeping a now 30-year-old classic truck on the road doing what it was built to do – adventure.

Part of our most recent rebuild program included a complete long-travel suspension from Total Chaos Fabrication. Although this is a significant departure from stock, it still utilizes original control arm mounting points and steering. This means that we are able to use all new factory Toyota Genuine steering components. Over our extensive travels we have found they last much longer than aftermarket options and therefore are much less expensive in the long run. This also equates to components that could withstand the life of our next trip instead of an impromptu replacement in the backcountry of Mongolia. Toyota Genuine inner and outer tie rod ends, lower ball joints, and pitman arm were installed.

Although we are currently using aftermarket T100 axles in our new suspension system it was prudent to use Toyota Genuine CV boots. These can withstand the extreme use of a long-travel suspension system better than any aftermarket option can. Once Toyota T100 front axles are available, they’ll get swapped in for maximum durability.

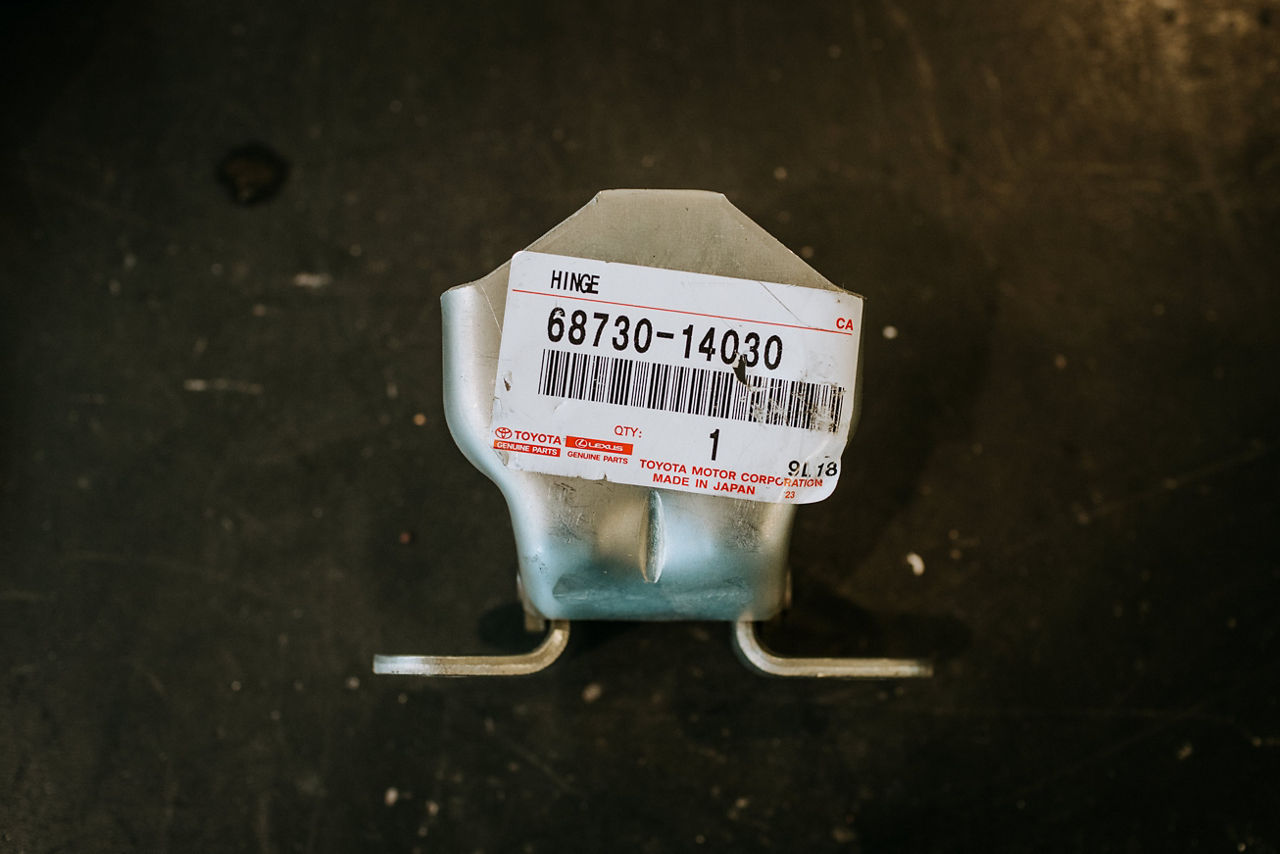

When you use a 30 year old truck as hard as we do, small things make a big difference. The door hinges became worn after countless cycles. I’m sure the thousands of kilometers of washboard roads in South America didn’t help. Replacement door hinges mean that rattles are a thing of the past. Just one more step towards making this truck feel like new again.

Before taking Little Red on its maiden shakedown run we felt it was right to give the venerable 22RE a little love. Tune up parts are and easy way to keep our 22RE running well. A distributor cap, rotor, motor oil filter, and air filter were all installed. We always keep a few Toyota 90915-YZZD1 motor oil filters in the truck for oil changes on the road.

Now that our chassis is refreshed and the suspension ready for an upcoming overland journey, we have a short list of other items to address. But that’s a story for next time.

Follow Richard and Ashley on their next overland adventure

Blog: www.desktoglory.com

Instagram: www.instagram.com/desktoglory / @desktoglory

YouTube: www.youtube.com/desktoglory