Select a province & language

Entrance to this website assumes you have read and agree to these Legal Terms and Conditions and the Privacy Policy.

Entrance to this website assumes you have read and agree to these Legal Terms and Conditions and the Privacy Policy.

By now, you’re probably well aware of how hybrid batteries can help cut emissions from vehicles. But what about cutting CO2 from buildings?

That’s exactly what’s happening at Toyota’s Honsha Plant in the Aichi prefecture of Japan.

As part of moves to reduce emissions from the plant’s energy management building to zero, Prius batteries are being repurposed to store energy that can then be used for electricity.

The building’s solar panels will generate electricity directly, but any excess will be saved in these recycled batteries.

It isn’t the only Toyota vehicle technology being harnessed to cut emissions from the building. Hydrogen technology from the Mirai will also play a role.

The stationary pure hydrogen fuel cells installed at the building are related to systems designed to power vehicles but adapted for office buildings.

Beyond the use of technology connected to Toyota vehicles, a range of other innovations will also help the facility achieve its zero emissions goal.

Each employee will be allowed to switch the air-conditioning and lighting on and off, and the use of natural lighting and natural ventilation will be maximized. These measures are expected to reduce electric power consumption and CO2 emissions by half. For more information visit Toyota’s global newsroom

This initiative is Japan is one example of how Toyota is working to fulfill its Plant Zero Emissions Challenge, which forms part of the Environmental Challenge 2050.

After all, we all need to do our bit to ensure a sustainable future. For Toyota, this means looking beyond simply reducing emissions produced as we all get from A to B.

Since vehicles don’t just contribute to CO2 emissions on the road, The Plant Zero Emissions Challenge involves refining production processes to use energy efficient technology and looking at alternative fuel sources.

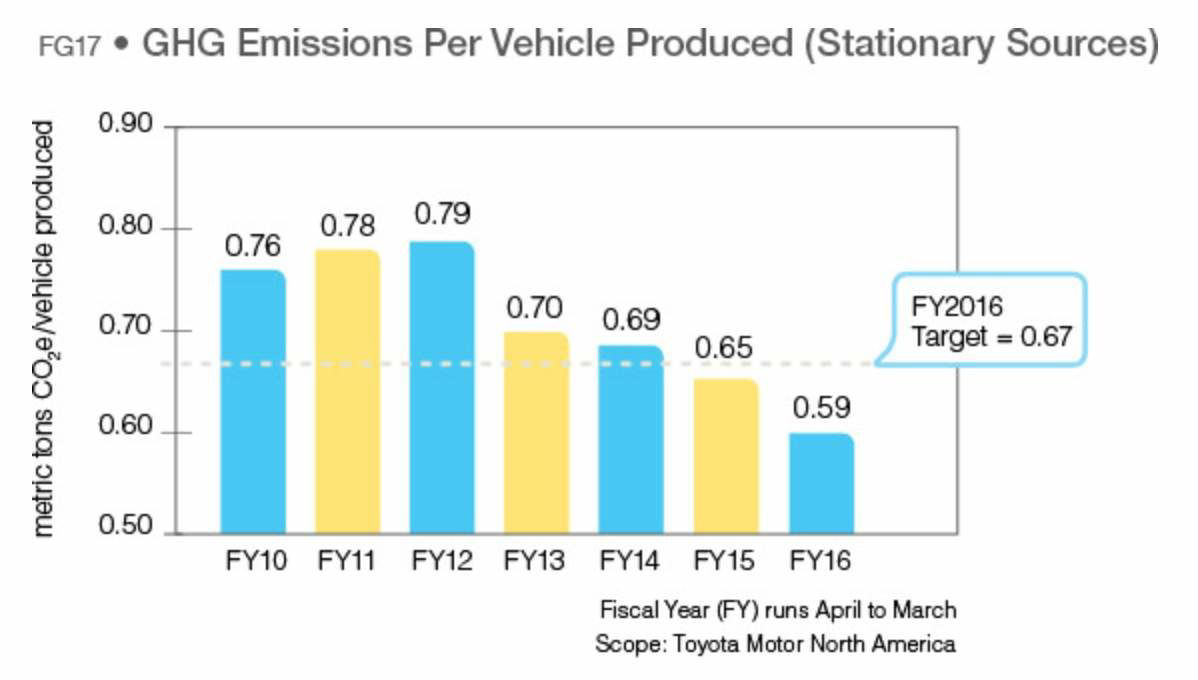

The impact of this is already starting to take effect. For example, data from the recently published in our 2016 North American Environmental Report shows that in North America CO2 emissions per vehicle product fell by 10 percent from 0.65 metric tons per vehicle produced to 0.59.

Toyota’s commitment to continual improvement means trying to make every part of the processes more efficient.

The Honsha zero-emissions building is a small step on the way to significant emissions reductions, and eventually to the target of a net positive impact on our planet.